A world-leading brand for collaborative robots, will once again be showcasing in 2019. TM Robot announces the operator series and introduces the TM palletizer, which integrates with the company’s robotic arm. This allows users to quickly set up processes and automatically correct staggered objects and pallet locations with a visual inspection using a proprietary, intelligent user interface. During product development, TM Robot also worked to develop a force control feature that automatically creates machining paths according to pre-set force settings. In order to meet a wide variety of applications in the industry as far as possible, TM Robot offers optimal solutions for future production facilities and supports people’s lives with philanthropic robots.

TM Robot Consolidates The Company’s Supply Chain To Enhance Competitiveness

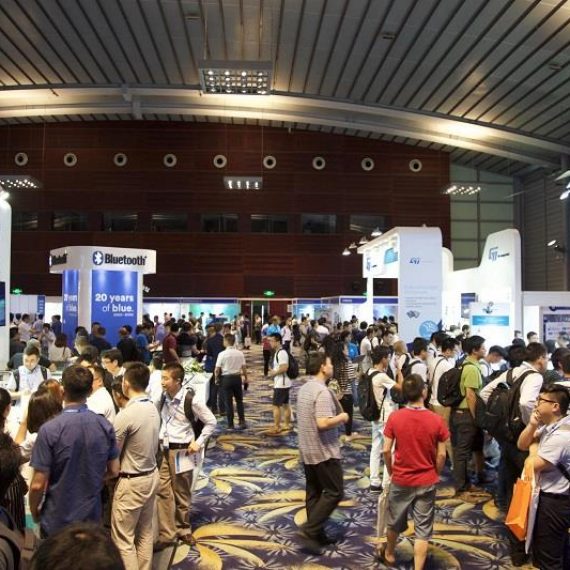

TM Robot will present the following device-related industrial partners at the exhibiton: All products have been successfully integrated into our built-in vision system and the user-friendly TMflow. This product diversity can enhance industrial niches and deepen special industrial applications, such as: In the electronics, automotive and conventional processing industries. TM Robot has set itself the goal of converting conventional manufacturing equipment into intelligent factories with high efficiency by offering optimal solutions.

Technological Breakthrough In Adjusting The Force Control

Conventional robotic arms find it difficult to create machining paths (curvature or surface) for deburring and polishing. Due to the cooperation, you can create machining paths automatically and then import them directly into the TM robot. This not only saves you time, it also eliminates the complexity of manual teaching points in the past. This is demonstrated on the TM5, with perfect editing in deburring and polishing, is achieved by a pre-set force control and a six-axis force sensor. This solution undoubtedly increases the efficiency of robotic arms in your production line.